Future CPUs & GPUs To Cost More As TSMC Doubles 2nm Price

TSMC is all set to almost double the price of it’s 2nm silicon wafers. This means that your CPUs and GPUs are likely to get more expensive.

In the world of computing, CPUs and GPUs makers consist of two types. Fabless and foundries. The fabless companies only design chips, while foundries actually manufacture them.

While Samsung and Intel (except recently) made their own CPUs, the likes of AMD, Nvidia, Qualcomm, Broadcom and others only design them. Most of the chips by these companies are manufactured by the Taiwanese giant TSMC.

TSMC is so big that it has almost 50% of market share when it comes to manufacturing advanced latest generation chips. Every company goes to them to get their latest processor manufactured.

This has allowed TSMC to become an almost monopoly and has allowed TSMC to charge exorbitant prices for its wafers.

Looks like it’s going to increase the prices even more.

2nm To Cost $30,000

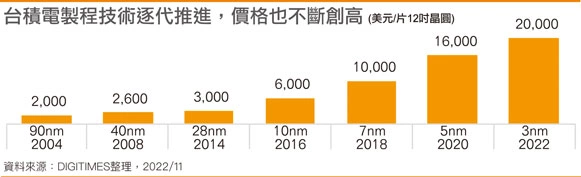

Taiwan based China Times reports (via Tom’s Hardware and Dan Nystedt) that TSMC is going to hike the prices of 2nm wafers to $30,000 per (300mm) wafer. This is almost double than what 5/4nm used to cost to the companies.

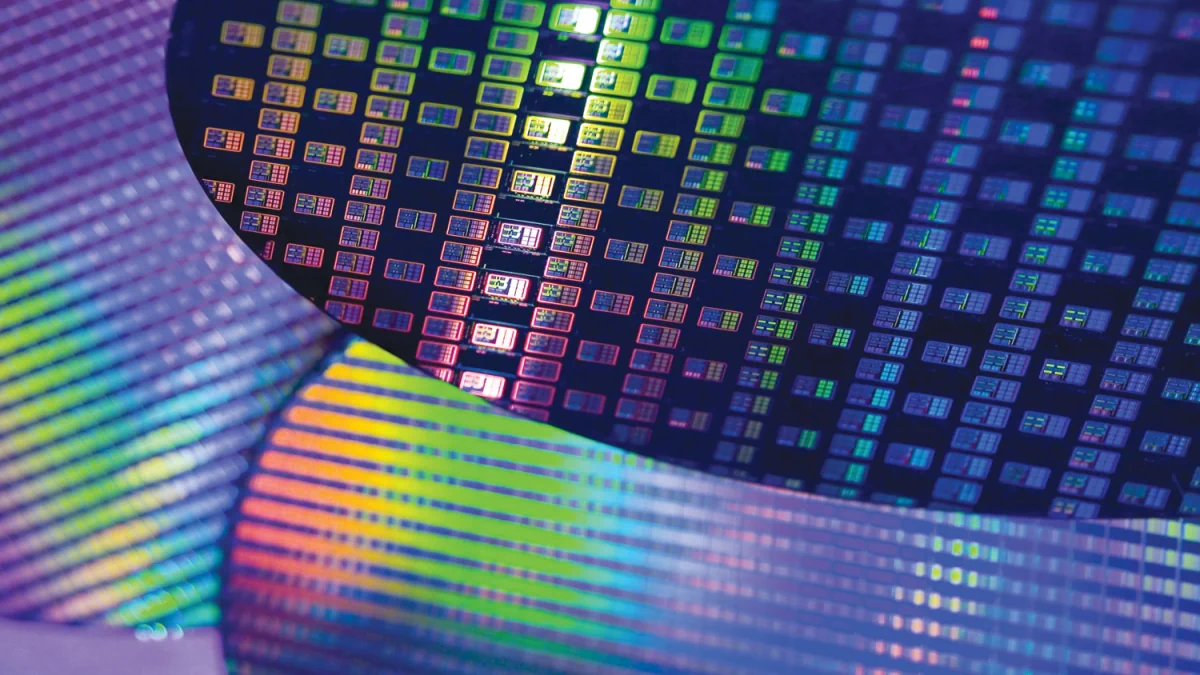

Two years ago we had reported how TSMC was charging $16,000 per wafer for the 5nm process and increased its prices to $20,000 per wafer for the 3nm process. A single wafer can make dozens of chips, depending on the chip size.

So if TSMC plans to charge chip designers $30,000 per wafer for the 2nm process, the increase is of 40% over 3nm’s cost, which is higher than the 25% hike which we saw with the 3nm process over the 5nm one.

The reasons for this move is the overall cost of manufacturing. The R&D and tools required to make advanced chips isn’t cheap. While the development cost of the 28nm process was $50 million, 16nm required an investment of $100 million. When advancing to 5nm, that became $550 million. 3nm additionally required a massive 4-5 billion of investment for R&D. That doesn’t count the cost of the factory, which required $15 to $20 billion to make.

The whole supply chain is important in silicon manufacturing. The R&D manpower, equipment, software, and materials all are very important and it often requires 7 to 10 years of planning for a single nm process. The 2nm is even more expensive due to the tools it requires. It requires the wafer to be thinner.

Additionally, Tom’s Hardware mentions how TSMC’s 2nm will offer nanosheet GAA transistors, allowing better performance and power control, NanoFlex tech allowing designers to combine differently powered libraries inside a single block. It will also have EUV double patterning. All these things require expensive tools.

Conclusion

The actual performance gain of the 2nm process over 3nm is 10% to 15% (at the same power and complexity) and power consumption by 25% to 30% (at the same clocks and complexity). The average increase of the transistor density is about 15%.

But does this mean 2nm should cost 40% more. Well, if costs are taken into consideration, then yes. But will companies be happy with it. Do they have any other options. We don’t think so. Intel’s 18a process manufacturing isn’t ready yet and we don’t know their yields. Samsung’s both 3nm and 2nm process are having bad yields, making many companies run away from it.

So the only option the likes of AMD, Nvidia, Qualcomm, Broadcom and others have is that they stick to TSMC. Which means the consumers will need to shell out more money for CPUs and GPUs if they want them.