Intel To Use Glass To Make CPU Base Substrates

Don't drop them. Fragile and made from glass.

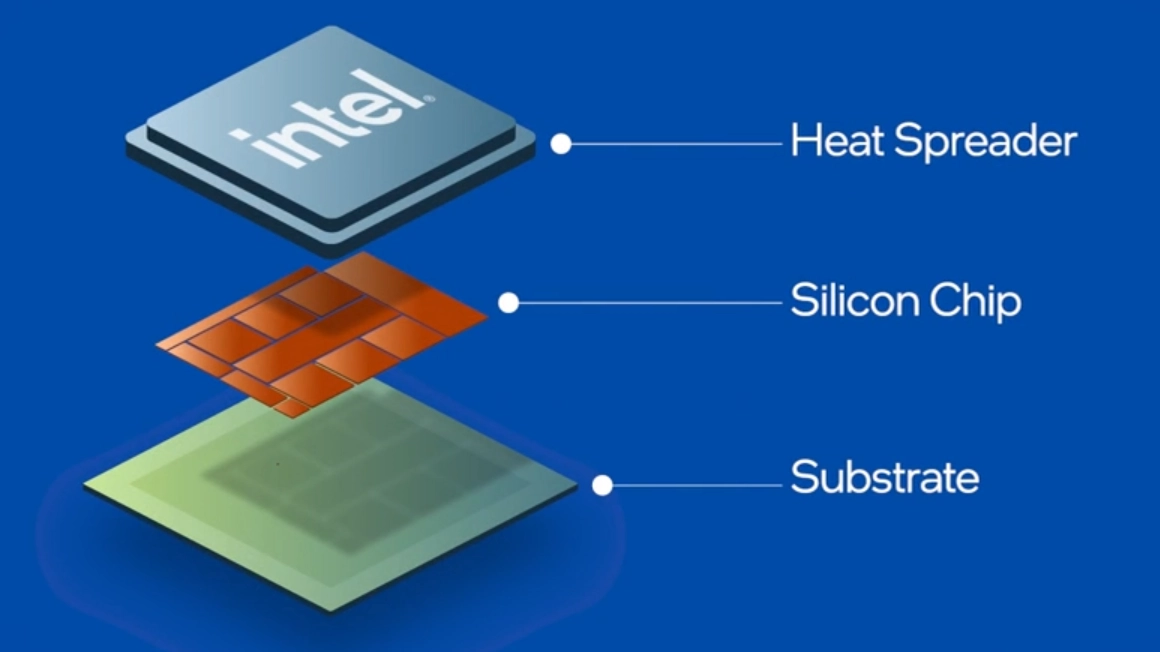

The substrate forms an important base for the processor. While they are made from organic materials these days, Intel wants to make them using glass instead.

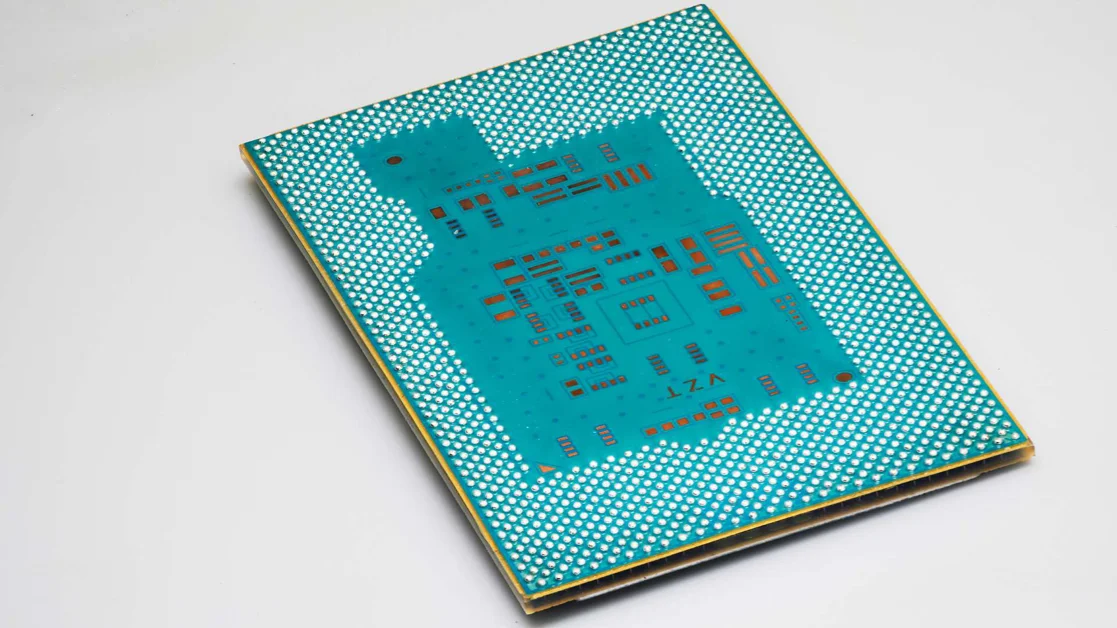

Computer processors, which form the most important part of computing, are not made of just silicon-based CPU chips themselves. They also contain substrates, which form the base of the processors.

The substrates are small circuits that contain the wires connecting the CPU chips and form the base of the processors.

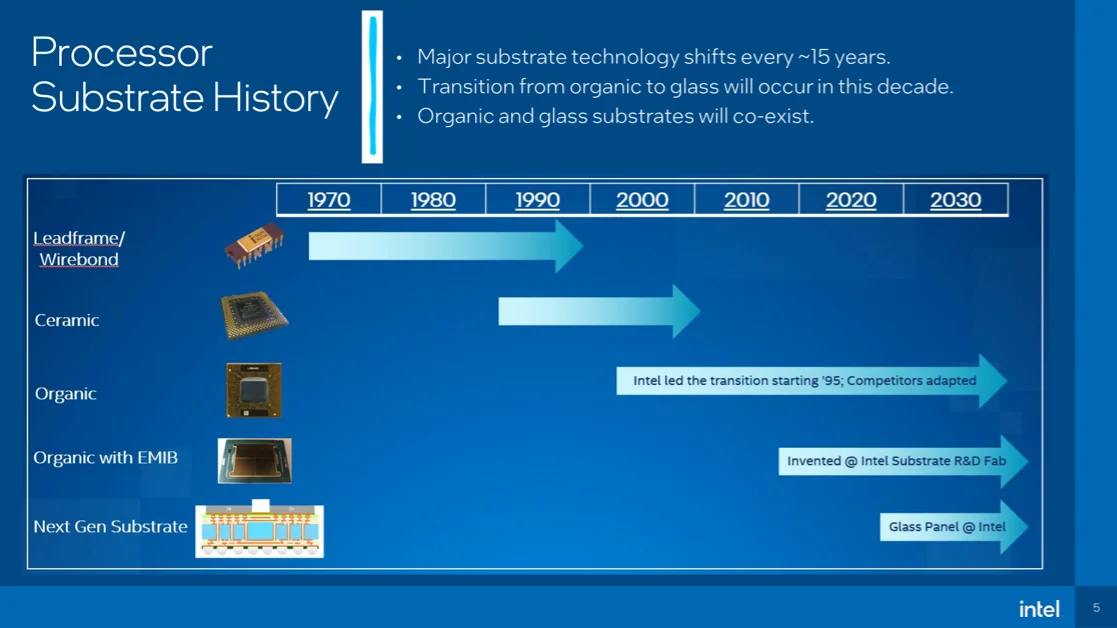

Years ago, processor substrates were made using leadframe / wirebond. That changed when the industry moved toward ceramic substrates. Then came organic substrates in the 1990s, whose rollout was led by Intel.

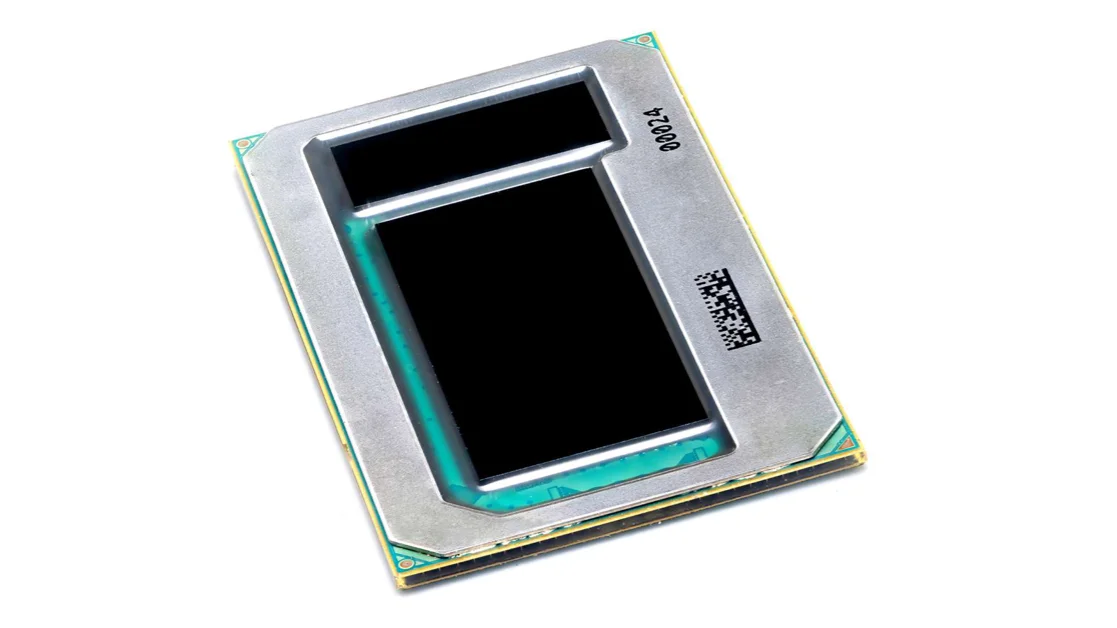

Since then, substrates have not seen many changes. Now organic substrates, which are mostly made of plastic, are not able to handle the advancement in processor packaging. So Intel has decided something new needs to be used to make them. Hence, Intel has decided to use glass instead.

Intel Processors To Be Made From Glass

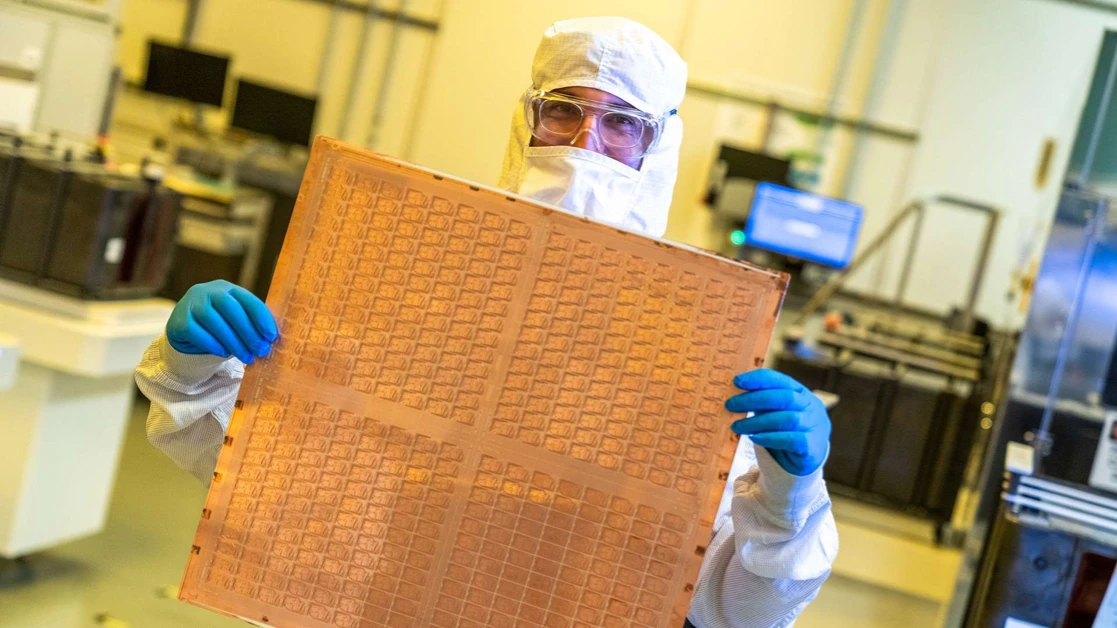

In an official announcement today, Intel said that it has developed the industry’s first glass substrate for advanced packaging of processors. This comes after Intel’s decade-long research into it.

Intel says that it’s a better replacement than the currently used organic substrates. Quoting the announcement:

Compared to today’s organic substrates, glass offers distinctive properties such as ultra-low flatness and better thermal and mechanical stability, resulting in much higher interconnect density in a substrate.

Reasons For This Move

Simply put, the more transistors, the faster the processor. As we are going into the single-digit nanometer (a marketing term) range of transistor sizes, making processors is getting very complicated. Reducing the size of the transistors inside chips is getting harder and harder.

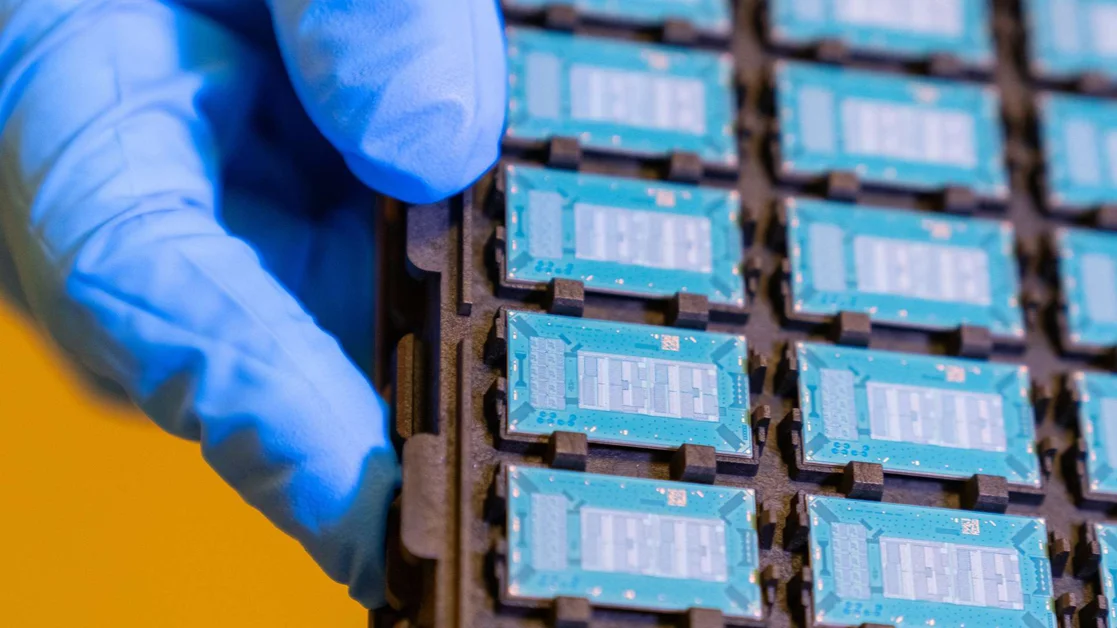

This is why processor makers are moving towards chiplet-based processors. Where a single processor is not made from a single chip, but instead contains multiple CPU chips inside a single processor.

The best example is AMD, which uses multi-chiplets in its Ryzen processors. But not just AMD, even Intel is moving towards a multi-chiplet approach, where it will start using tiles on its processors starting with the Meteor Lake series of processors.

So something is required to connect these chiplets or tiles properly. This is why processor substrates become even more important.

Quoting Intel:

“As the demand for more powerful computing increases and the semiconductor industry moves into the heterogeneous era that uses multiple “chiplets” in a package, improvements in signaling speed, power delivery, design rules and stability of package substrates will be essential. Glass substrates possess superior mechanical, physical and optical properties that allow for more transistors to be connected in a package, providing better scaling and enabling assembly of larger chiplet complexes (called “system-in-package”) compared to organic substrates in use today. Chip architects will have the ability to pack more tiles – also called chiplets – in a smaller footprint on one package, while achieving performance and density gains with greater flexibility and lower overall cost and power usage.”

Glass Benefits

Intel has given many reasons and benefits for using glass over the currently used organic substrates:

“Glass substrates can tolerate higher temperatures, offer 50% less pattern distortion, and have ultra-low flatness for improved depth of focus for lithography, and have the dimensional stability needed for extremely tight layer-to-layer interconnect overlay. As a result of these distinctive properties, a 10x increase in interconnect density is possible on glass substrates. Further, improved mechanical properties of glass enable ultra-large form-factor packages with very high assembly yields.”

Simply put. Glass is flatter, has better stability and has better connectivity. Making it ideal for using it as a substrate that is going to be used in connecting CPU chiplets.

Rollout Date

Intel mentions that by 2030, the transistors on a CPU package will reach 1 trillion. So such technological innovations are required.

This is in addition to innovations such as RibbonFET, which is Intel’s version of GAAFET which is an advanced method of making CPU transistors. Not to forget PowerVia backside power delivery, which changes how processors are powered, improving the CPU’s efficiency.

Intel believes that such innovations mean that glass substrates will be required going forward. It says that glass substrates are going to be used in CPU processors starting in the later parts of this decade.

The photos above show that it’s being tested on smaller processors too, meaning it will not be limited to just server processors but will be used on desktop and notebook processors too. Meaning, years later, the CPU you will buy might use these new glass substrates.

Here’s hoping that people don’t drop these CPUs while installing them. It would be very expensive to do so. Maybe people should ask Intel to make sure there is one free glass replacement available for every single CPU made by them.